Maintaining the health of infrastructure, such as roads, bridges, sidewalks, and public buildings, is critical for the community's safety, efficiency, and overall well-being.

Early detection of cracks in these structures prevents minor issues from escalating into major failures, which can lead to costly repairs, disruptions, and even accidents.

Bringing AI to infrastructure challenges such as crack detection is a proactive approach to maintenance, enabling companies, government agencies, and other entities to address problems promptly and efficiently.

The following blog post will address the following topics related to quality data labeling in infrastructure crack detection:

- How are images collected in infrastructure crack detection?

- Data labeling in infrastructure crack detection

- Machine learning models deployed into production

- Advantages of early crack detection

- Importance of high-quality data in infrastructure crack detection

- Importance of quality control in infrastructure crack detection

- How Accelerated Annotation can help

How are images collected in infrastructure crack detection?

Images are collected through various means, including ground and aerial drones, handheld devices, and vehicle-mounted cameras, providing comprehensive coverage of the infrastructure in question.

Data labeling in infrastructure crack detection

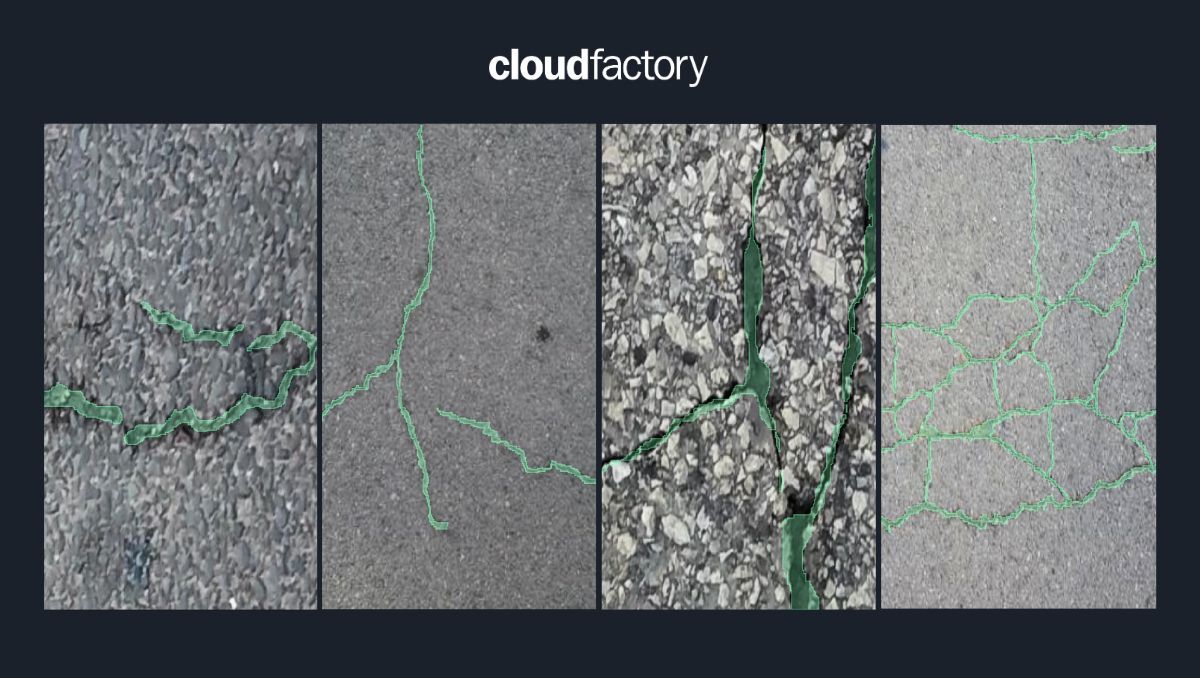

Expert annotators process, analyze and label the images to identify different types of cracks, such as hairline cracks, structural cracks, or potholes.

The labeling process involves segmenting the crack's shape, categorizing its severity, and suggesting the underlying cause.

From the ML perspective, developers solve a segmentation problem complicated by instance attributes. With a sufficiently large and accurately labeled dataset, ML models are trained to detect and classify cracks in new, raw images.

These models learn to recognize patterns and features associated with different types of cracks, enabling them to identify issues automatically in the vast array of images collected from the environment where the infrastructure asset lives.

Labeled data for an infrastructure health Instance Segmentation use case. Data origin - Concrete Compressive Strength dataset.

Machine learning models deployed into production

ML models are next deployed into the production environment, where they continuously analyze incoming data from the field, setting the groundwork for a predictive maintenance approach.

The system flags areas that require attention, providing engineers and maintenance teams with precise locations and details about the detected cracks.

Beyond identifying existing cracks, the data and trends gathered by the system can help predict which areas are most at risk of developing problems in the future, enabling preemptive repairs and strategic planning.

This part of the algorithm is based on the probabilistic approach and may not be perfect, but it's a good starting point for humans to dig deeper.

Advantages of early crack detection

Here are three advantages of using AI for early crack detection in infrastructure asset management:

- Reduces the risk of accidents and injuries, ensuring a safer infrastructure environment. Addressing issues early can prevent minor cracks from becoming major problems through predictive maintenance, reducing the need for extensive repairs or replacements and saving significant amounts of money over time.

- Automating parts of the detection process widens the existing bottlenecks and streamlines the maintenance workflow, allowing companies or agencies to allocate resources more effectively and maintain infrastructure with greater efficiency.

- Accumulating labeled infrastructure health data allows planners and engineers to make informed decisions about where to focus maintenance efforts and how to allocate budgets for future infrastructure projects.

The ultimate goal is to create a fully automated monitoring system that detects and classifies infrastructure defects and accurately predicts future vulnerabilities, setting a new standard for infrastructure asset management and overall health.

Importance of high-quality data in infrastructure crack detection

Finding cracks in structures like buildings and bridges is tough. Developing models for crack detection underscores the necessity of high-quality, accurately labeled datasets—both raw images and annotations must be very qualitative, as the effectiveness of supervised learning algorithms hinges on the volume and accuracy of the training data.

Accurate crack detection depends on two factors: 1) precise marking of cracks within images and 2) detailed classification based on width, length, and severity. These details are crucial for training the algorithm to accurately translate data to real-world applications.

Effective image preprocessing can significantly enhance model performance and generalization capabilities. Furthermore, utilizing the transfer learning technique, leveraging pre-trained models on similar tasks, can expedite the training process and tweak the performance to the desired metrics such as mean Average Precision.

However, the success of these advanced ML techniques is contingent upon the initial step of meticulous data labeling, which establishes the ground truth for the model to learn from.

Importance of quality control in infrastructure crack detection

Making sure labels are the same and correct for a vast dataset requires careful quality control processes. This includes experts comparing labels and maybe using ML tools to suggest labels, always checked by humans in the loop.

For ML engineers, it's not just about building models: they also need to manage how data is labeled, understand how models make decisions, and improve labeling rules based on how models perform.

This holistic approach ensures the development of robust, reliable ML solutions for crack detection in infrastructure, setting a benchmark for precision and operational efficiency in the field.

How Accelerated Annotation can help

CloudFactory's Accelerated Annotation is perfect for ML engineers focused on infrastructure crack detection projects and other infrastructure asset management issues, addressing many of the challenges associated with high-quality data labeling.

This platform leverages a novel combination of advanced ML algorithms and a skilled workforce to annotate large datasets with high precision and speed. By employing semi-automated labeling tools, Accelerated Annotation can significantly reduce the time required for labeling without compromising the accuracy and detail essential for training effective ML models.

For ML engineers, this means access to consistently labeled, high-quality datasets that are ready for use in training ML algorithms.

The platform's ability to handle complex labeling tasks, including the nuanced classification of cracks based on various characteristics, aligns with the technical requirements for developing sophisticated predictive maintenance models.

The Accelerated Annotation workflow includes rigorous quality control processes overseen by domain experts, ensuring that the labeled data meets the high standards necessary for reliable model performance.

CloudFactory's Accelerated Annotation can also streamline the data preparation phase of ML projects, allowing engineers to focus more on model architecture and less on the labor-intensive process of data labeling.

The platform's scalability and flexibility also mean that ML projects can be dynamically adjusted based on changing requirements or project scopes, providing a tailored approach to each unique challenge.

Accelerated Annotation enables the development of more accurate, efficient, and impactful crack detection models for infrastructure maintenance and asset inspection.

Let’s look at a scenario to bring this all to life:

Meet the client

Roads get cracks, they're dangerous and expensive. So, a state transportation agency uses smart cameras on maintenance vehicles to capture high-resolution road surface images. They want to develop an ML model capable of identifying, classifying, and localizing cracks in real time, facilitating immediate decision-making regarding maintenance priorities.

Their challenge

Creating an ML model that can accurately and efficiently process large amounts of image data under various lighting and weather conditions.

Their model must distinguish between different types of cracks (e.g., longitudinal, transverse, alligator cracking) and assess their severity to prioritize repairs. This requires a large, well-labeled dataset that accurately reflects the diversity of cracks and road conditions.

The solution

Step 1: Data collection and preparation

Maintenance vehicles equipped with high-definition cameras capture images of the highway surfaces. These images are normalized and augmented to ensure the model is trained on a diverse set of conditions.

Step 2: Data labeling with a trusted annotation platform

The Accelerated Annotation platform annotates images with high accuracy. Labels indicate the presence of cracks, the type of crack, orientation, and severity, based on predefined criteria. Semi-automated tools within the platform expedite the labeling process, while human oversight ensures accuracy and consistency. The labeled dataset includes metadata for each image, such as the location and environmental conditions, enriching the training data for more contextual learning.

Step 3: Model development and training

AI-enhanced data labels tailored for object detection and classification are used to process the labeled images. Transfer learning from pre-trained models on similar tasks accelerates the training phase and enhances model accuracy. Continuous integration of newly labeled data allows for iterative model refinement, ensuring the system adapts to new patterns or variations in crack appearances.

Step 4: Deployment and real-time analysis

The trained model is deployed on edge computing devices in maintenance vehicles, enabling real-time analysis of road conditions. As vehicles capture new images, the model identifies and classifies cracks, with results immediately relayed to a central maintenance system. This system prioritizes repairs based on crack severity and location, optimizing maintenance crew dispatch.

Step 5: Feedback loop for continuous improvement

Data from field inspections and repair outcomes are fed back into Accelerated Annotation, where additional annotations may refine the model's understanding of crack severity and repair urgency. This feedback loop ensures the model remains effective over time, adjusting to changing conditions and maintenance practices.

The results

By harnessing CloudFactory's Accelerated Annotation for high-quality data labeling, the client's ML model continuously evolves and adapts, leading to safer highways and better use of maintenance resources.

CloudFactory's Accelerated Annotation tackles the challenge of high-quality data labeling, enabling prompt, accurate, and AI-powered crack detection. Join the growing number of companies trusting this solution to uncover vulnerabilities, optimize infrastructure budgets, and pave the way for safer, more innovative assets.